Signals are used to record the process values, states or counter readings of an application or process. For example, a Signal can represent a temperature value, digital value, text value or counter value.

Use the Plus sign to create a new Signal. If you want to edit a Signal, click the button (the area around the Plus sign) to get a list of all existing signals. From there you can select the signal to be processed.

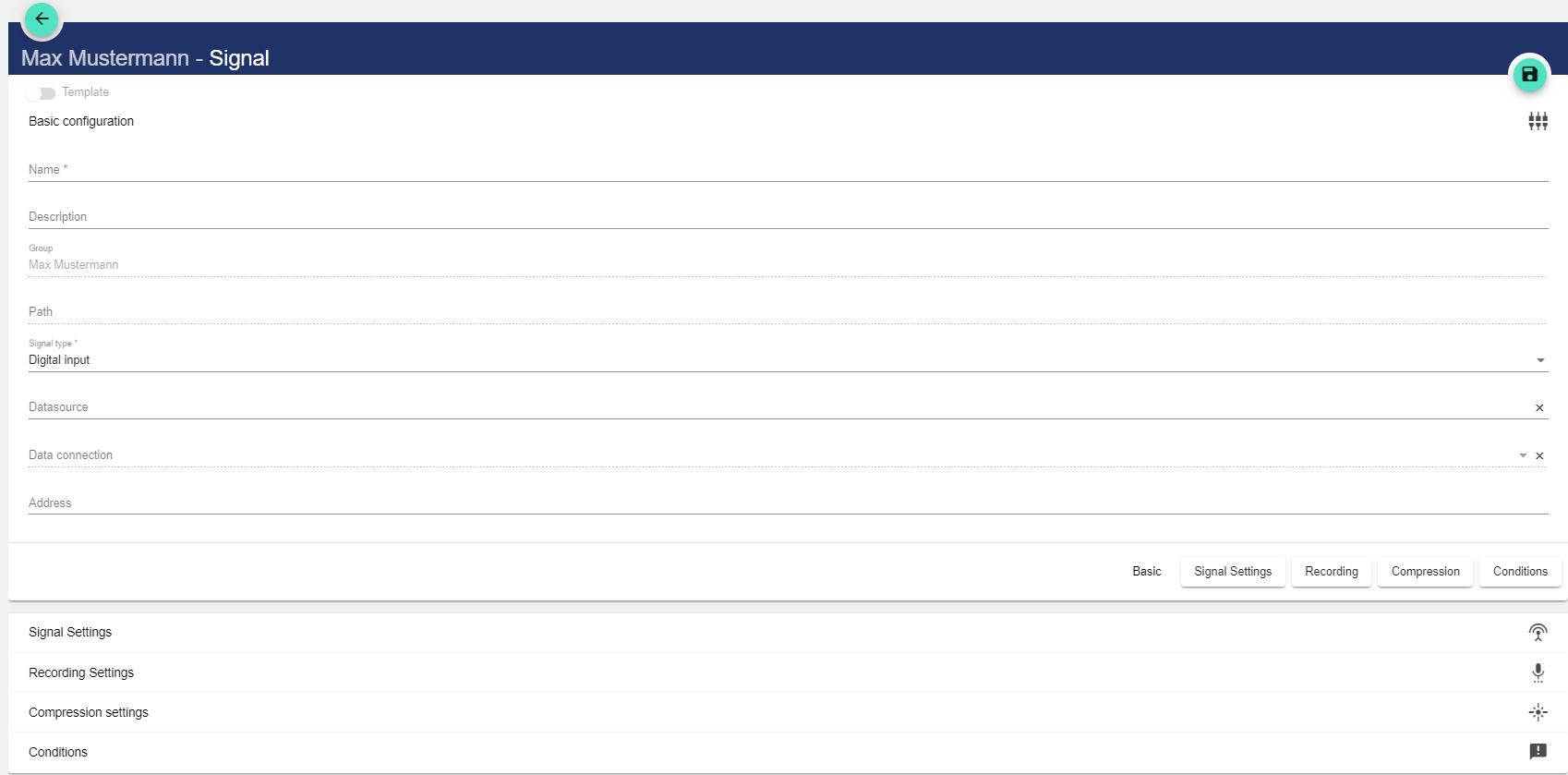

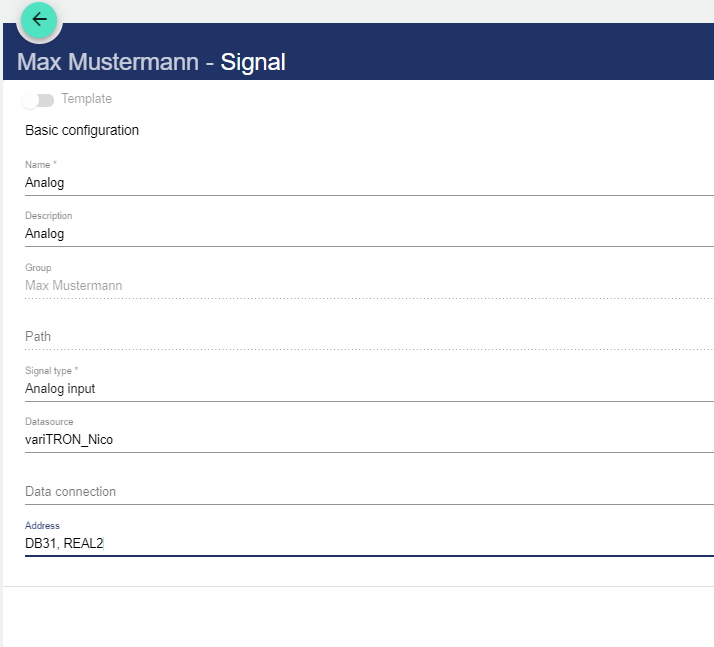

Basic Configuration

-

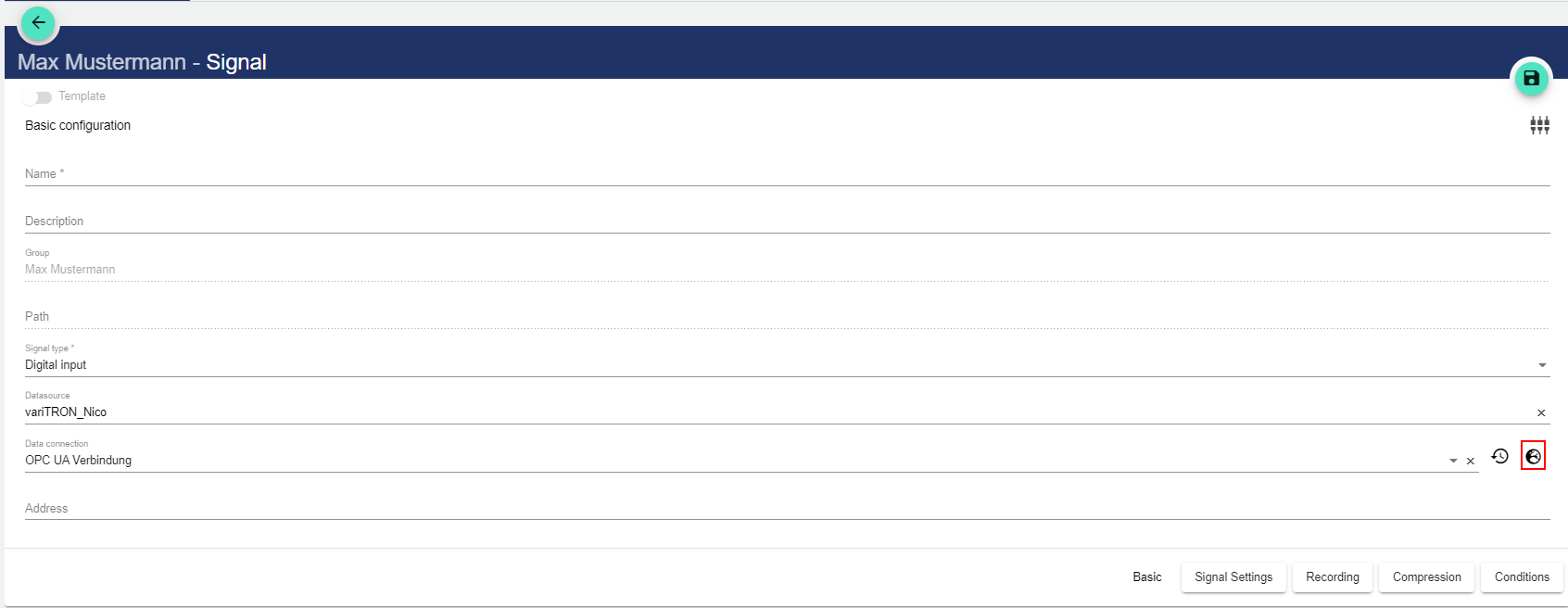

Assign the name of the Signal in the Basic Configuration. The Description field is optional. The Signal can also be created as a "template" (currently inactive). This allows you to simply add individual fields to the template in order to create new signals. The "Group" field shows the Group in which this Signal was created. The path is generated automatically by the system.

-

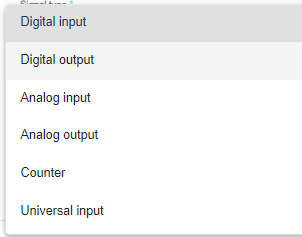

Selecting "Signal type" opens another drop-down menu.

|

Digital input |

Acquires data in digital binary form (On/Off or 1/0) as input |

IoT platform receives IoT device data. |

|

Digital output: |

Emits acquired data in digital form (On/Off or 1/0) |

IoT platform sends data to the IoT device. |

|

Analog input |

Acquires data in analog form as input. |

IoT platform receives IoT device data. |

|

Analog output |

Outputs the acquired data in analog form. |

IoT platform sends data to the IoT device. |

|

Counter |

Acquires data as a count value (1, 2, 3, 4, ...). Resetting to 0 is possible. |

The IoT platform receives IoT device data and also sends data to the IoT device. |

|

Universal input |

Acquires general data from your system, e.g. text values |

IoT platform receives IoT device data. |

|

Universal output |

Outputs general data, e.g. text values |

IoT platform sends data to the IoT device. |

-

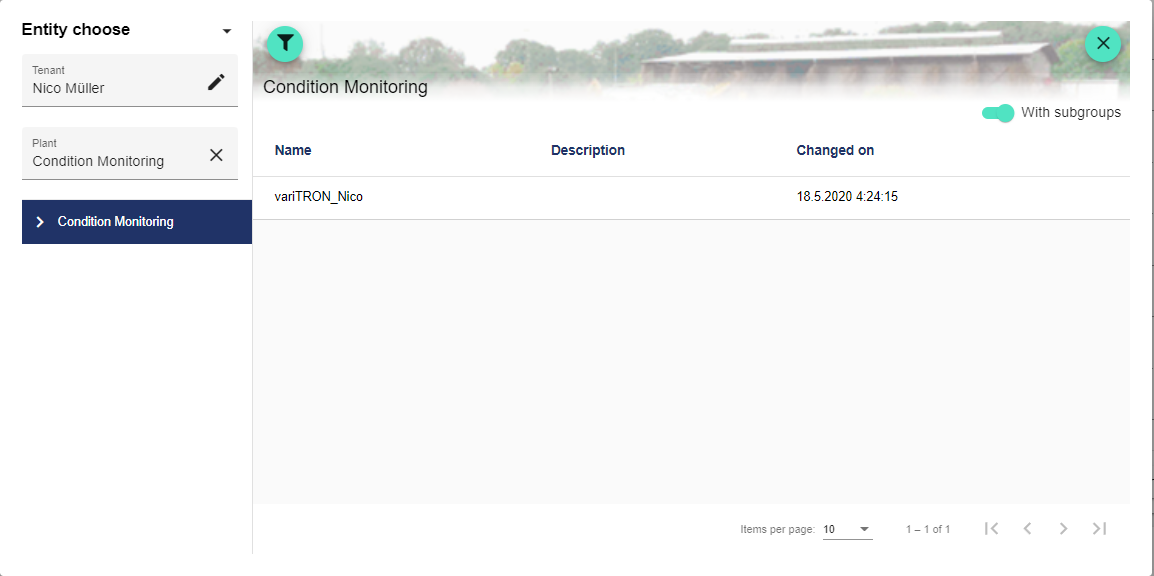

Clicking the "Data Source" field opens another window. A previously created Datasource can be selected there.

-

Clicking the "Data Connection" field opens another window. A previously created Data connection can be selected there.

-

The addresses in OPC UA, Modbus TCP and PROFINET (S7 TCP) are structured as follows:

OpcUa:

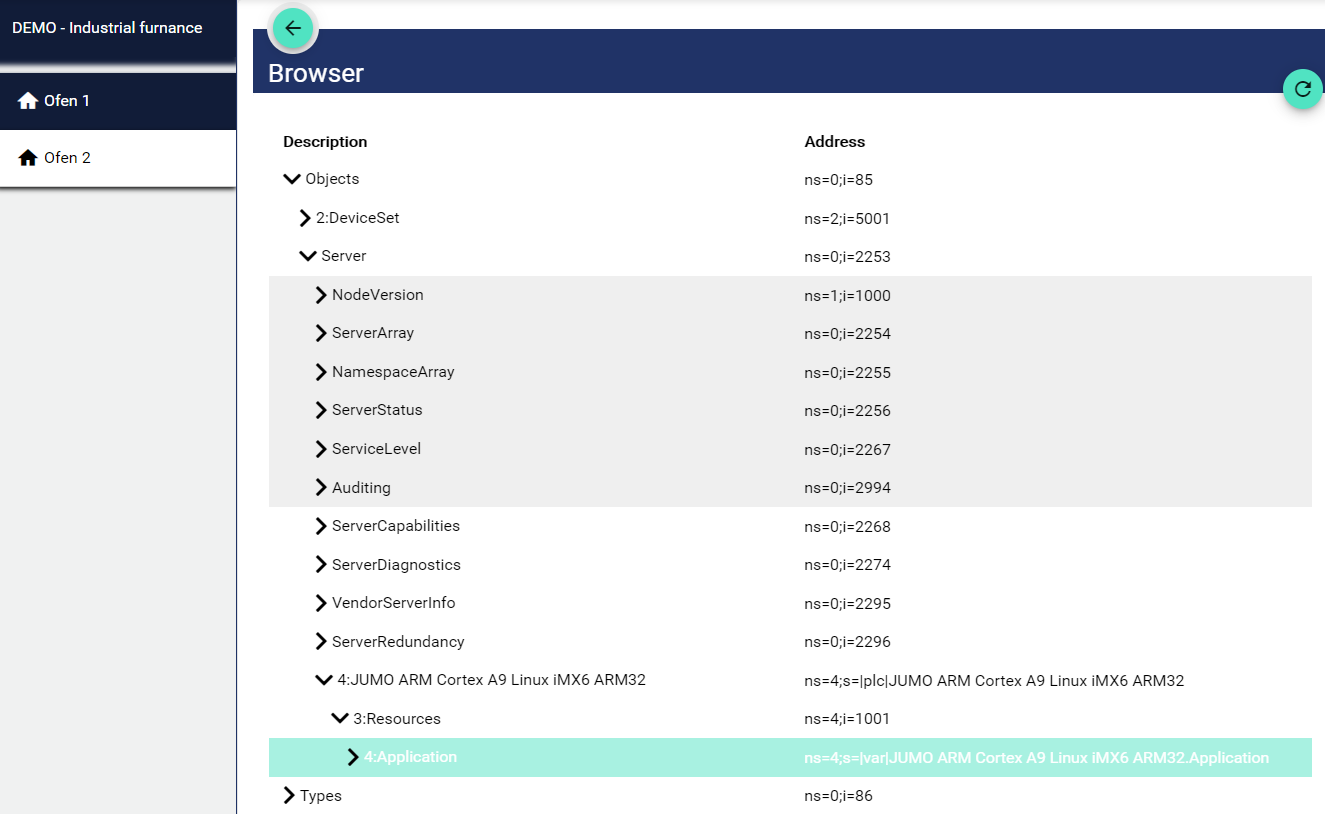

In OpcUa, the "Browse" function can be used to access the addresses within the controller (variTRON) via the "Globe" symbol.

The OPC UA variable can then be selected in the JUMO variTRON via the following path.

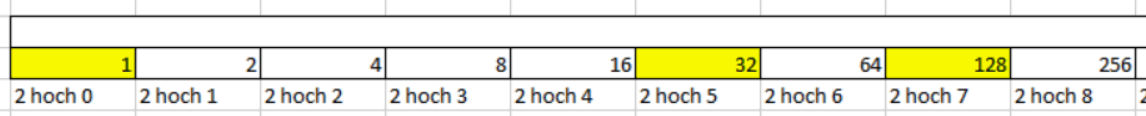

Modbus:

In Modbus, the "address" is composed of 40,000 or 30,000, including the digit indexed from 0. This means that if the specified original does not start at 0, it is adjusted accordingly. With a start index of 0, the offset can thus be added directly to 40,000 from the Modbus. With a start index of 1, as here in the table for example, +1 must be added to the offset. It follows that we must start with 40.001:WSREAL. A simpler and equally functional notation would be: 4xdecimalvalue+1:type or in the example: 4x34.817:WSREAL. The 3x addresses are for reading variables; the 4x addresses are for reading and writing variables.

3x-addresses= R/O (Read only) - variable

4x = R/W (Read/Write) - variable (see table)

Here is an aid to conversion: Binary-Decimal-Hexadecimal Converter

|

Examples |

Hex |

Dec |

"Address" of the Cloud and SCADA application |

|

Analog variable 1 (Modbus frame) |

0x8800 |

34.816 |

4x34817:WSREAL |

|

Analog variable 2 (Modbus frame) |

0x8802 |

34.818 |

4x34819:WSREAL |

|

Analog variable 3 ("direct") |

0x1075 |

4.213 |

4x4214:WSREAL |

|

Analog variable 4 ("direct") |

0x1077 |

4.215 |

4x4216:WSREAL |

|

Digital variable 1 (Modbus frame) |

0x8804 |

34.820 |

4x34821:INT |

|

Digital variable 2 (Modbus frame) |

0x8805 |

34.821 |

4x34822:INT |

|

Digital variable 3 ("direct") |

0x1373 |

4.979 |

4x4980:INT |

|

Digital variable 4 ("direct") |

0x1374 |

4.980 |

4x4981:INT |

|

Integer variable 1 ("direct") |

0x11F2 |

4.594 |

4x4595:INT |

|

Integer variable 2 ("direct") |

0x11F4 |

4.596 |

4x4597:INT |

|

External text 1 ("direct", e.g. LS 700)* |

0x1540 |

5.440 |

4x5441:CHAR,244 |

|

External text 2 ("direct", e.g. LS 700)* |

0x15BA |

5.562 |

4x5563:CHAR,244 |

|

External text 3 ("direct", e.g. LS 700)* |

0x1634 |

5.684 |

4x5685:CHAR,244 |

-

The data type for text signals corresponds to: " Char[244] ".

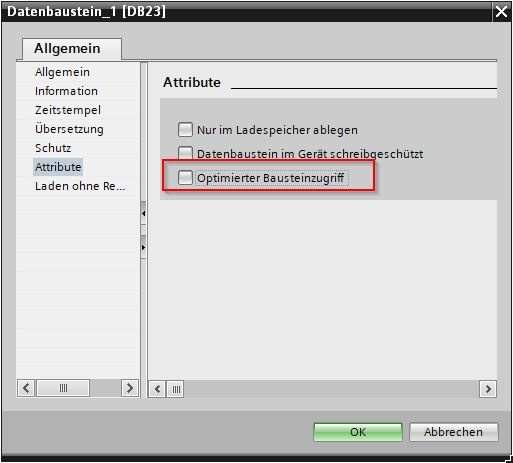

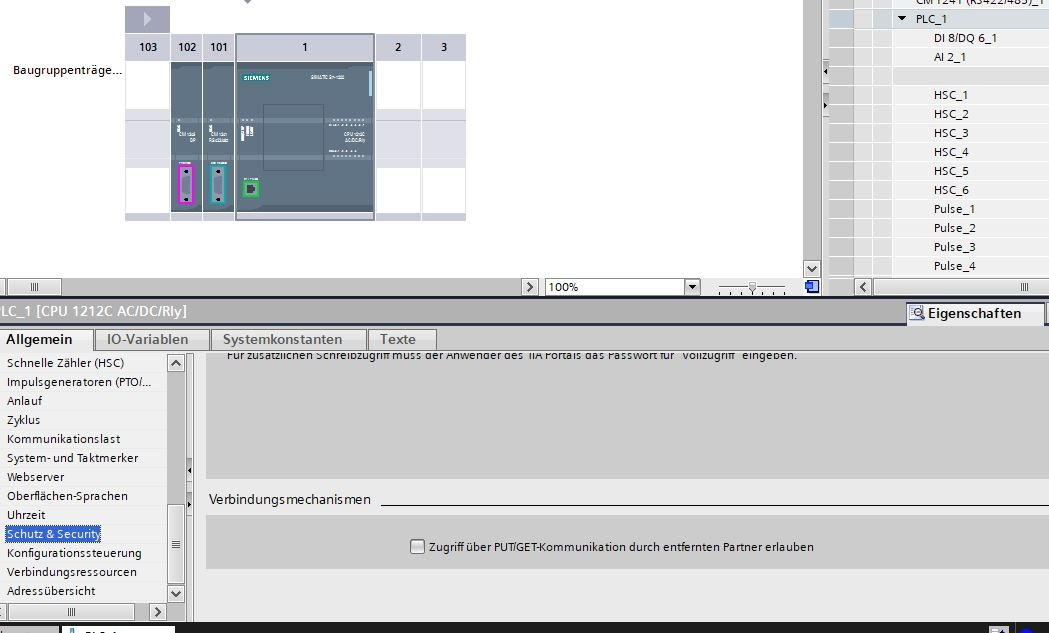

PROFINET (S7 TCP):

Addressing the signal occurs according to the format:<data block number,> <data type><byte offset><.array length>

Here an example:

Example with explanation:

|

DB31, |

REAL |

2 |

|

data block number: accessed database |

data type: accessed data type |

byte offset: data centre to be accessed |

|

S7 PLC |

Node-Red |

|

MR30 |

MD30 as REAL |

|

DB10,LR32 |

LREAL by Byte-Offset 32 in DB10, only for S7-1200/1500 |

|

DB10,INT6 |

DB10.DBW6 als INT |

|

DB10,I6 |

DB10.DBW6 als INT |

|

DB10,INT6.2 |

DB10.DBW6 and DB10.DBW8 in an array with length 2 |

|

PIW30 |

PIW30 as INT |

|

DB10,S20.30 |

String at offset 20 with a length of 30 (actual array length 32 due to the format of the string type, length byte is read/written). |

|

DB10,S20.30.3 |

Array with 3 strings at offset 20, each with a length of 30 (actual array length 32 due to string type format, length byte is read/written). |

|

DB10,C22.30 |

Character array at offset 22 with length 30 (best not to use with strings, because the length byte is ignored) |

DB38,S0.256

data block number: DB38 is the database number;

data type with byte offset: S0 is for specifying a string with offset 0 in the database;

array length: 256 for specifying the string is 256 bytes long.

Other examples:

DB10,DT0 - Date and time

DB10,DTZ0 - Date and time in UTC

DB10,DTL0 - DTL in newer PLCs

DB10,DTLZ0 - DTL in newer PLCs in UTC

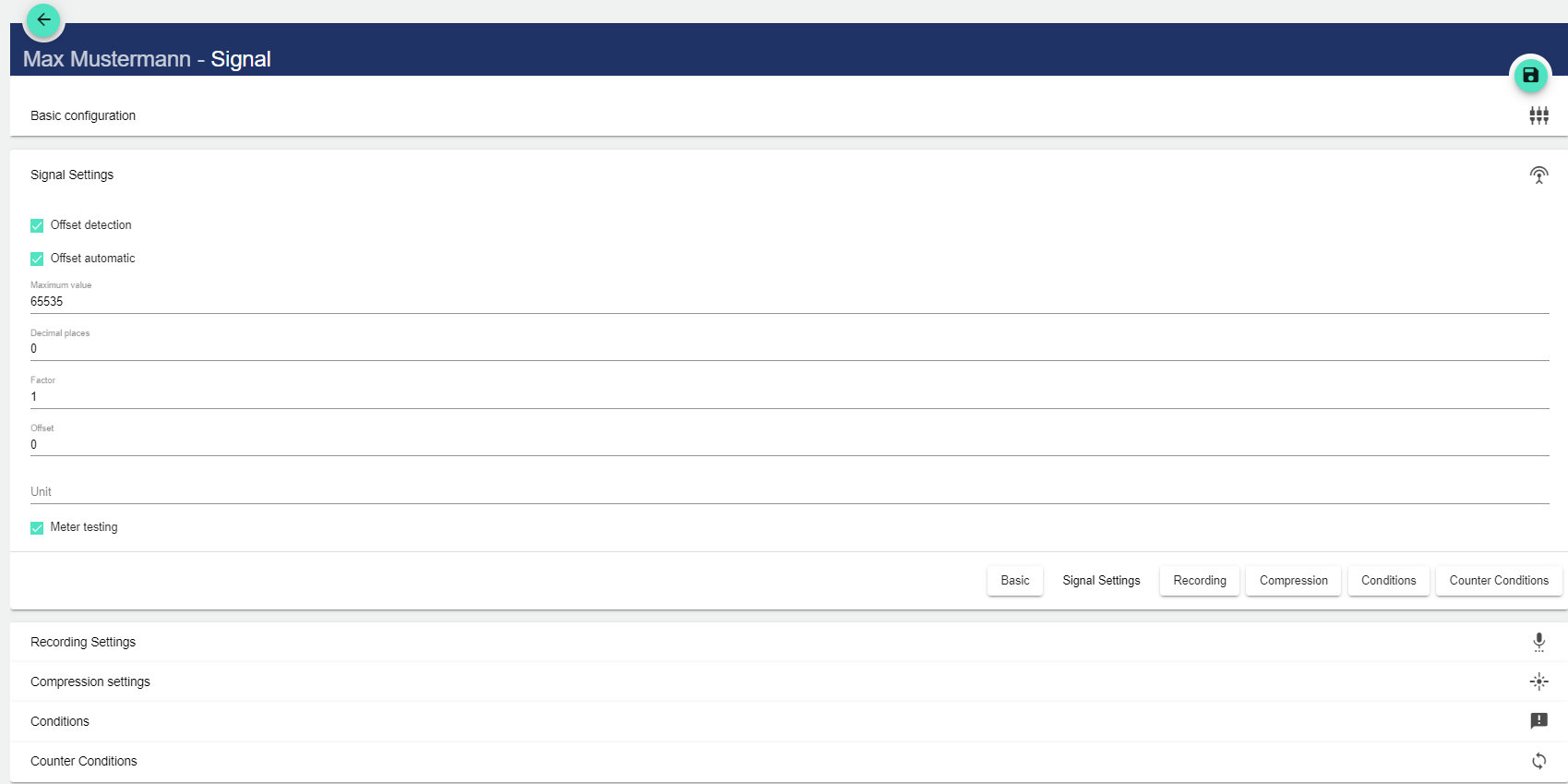

Signal settings

The signal settings depend on the signal type. This item is not available for the universal input / universal output type.

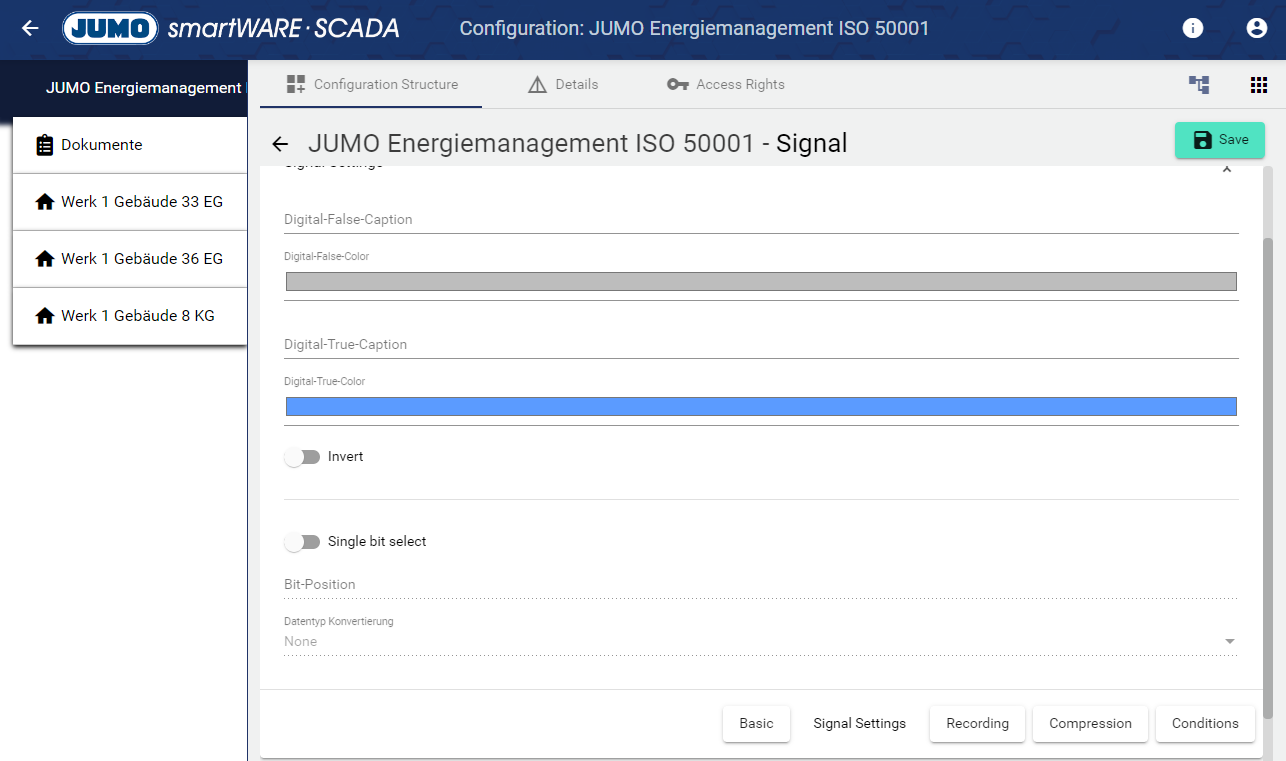

Digital input / output

-

Digital off label is displayed when the signal is off; can be reassigned and a color can be selected.

-

Digital on label is displayed when the signal is on; assign and a color can be selected.

-

Activating the "Invert" switch negates or inverts the signal.

-

By activating the " Single bit select" switch, a single bit can be analyzed. The advantage of this is that several pieces of information, such as several alarm values, can be read out from just one signal. In the lower field it can be selected into which data type the signal is converted. With an "Integer" e.g. all numbers between 0 and 65.535 can be represented with 16 bits. If the number 161 is transmitted, this means that bit 0, bit 5 and bit 7 are "TRUE", the rest is "FALSE". With the "bit select" one queries so to speak an integer at only one certain bit position, in order to identify thus several conditions or alarms from one signal.

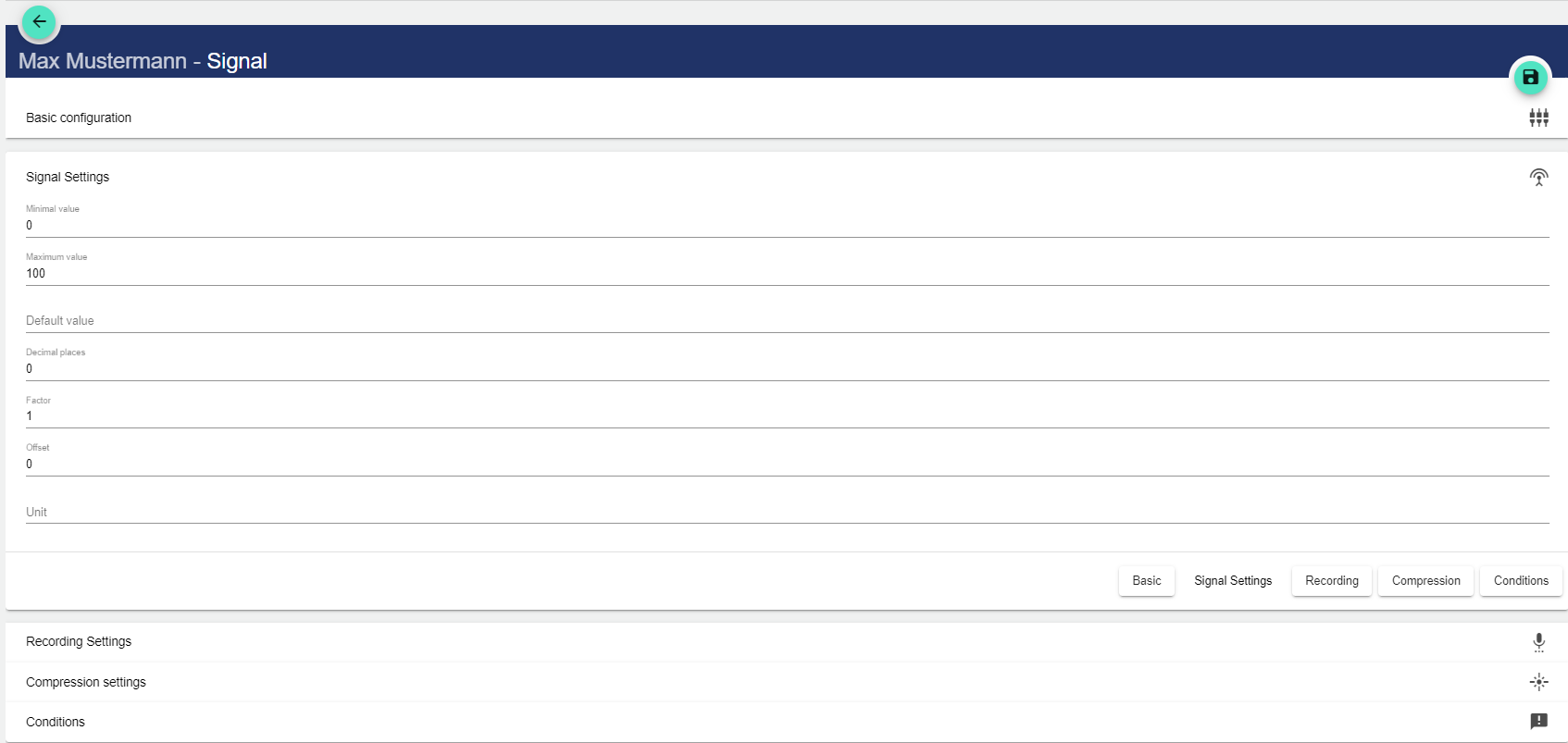

Analog input / output

-

Assign a minimum/maximum value that can be detected by the analog signal input or output from the analog signal output. Values above and below this are also recorded. However, when setting a value make sure not to exceed certain values.

-

Set a default value if no value has been acquired/output yet.

-

By adding decimal places, you can set the precision with which the signal is to output the values of your plant, as these are only used for the display in the system.

-

The factor is multiplied by the original value of the signal.

-

The offset specifies the fixed value by which the original value is shifted in the positive or negative direction (e.g.: value shift +1).

-

The unit is the measured value to be displayed. (e.g.: V or m³/h)

Counter

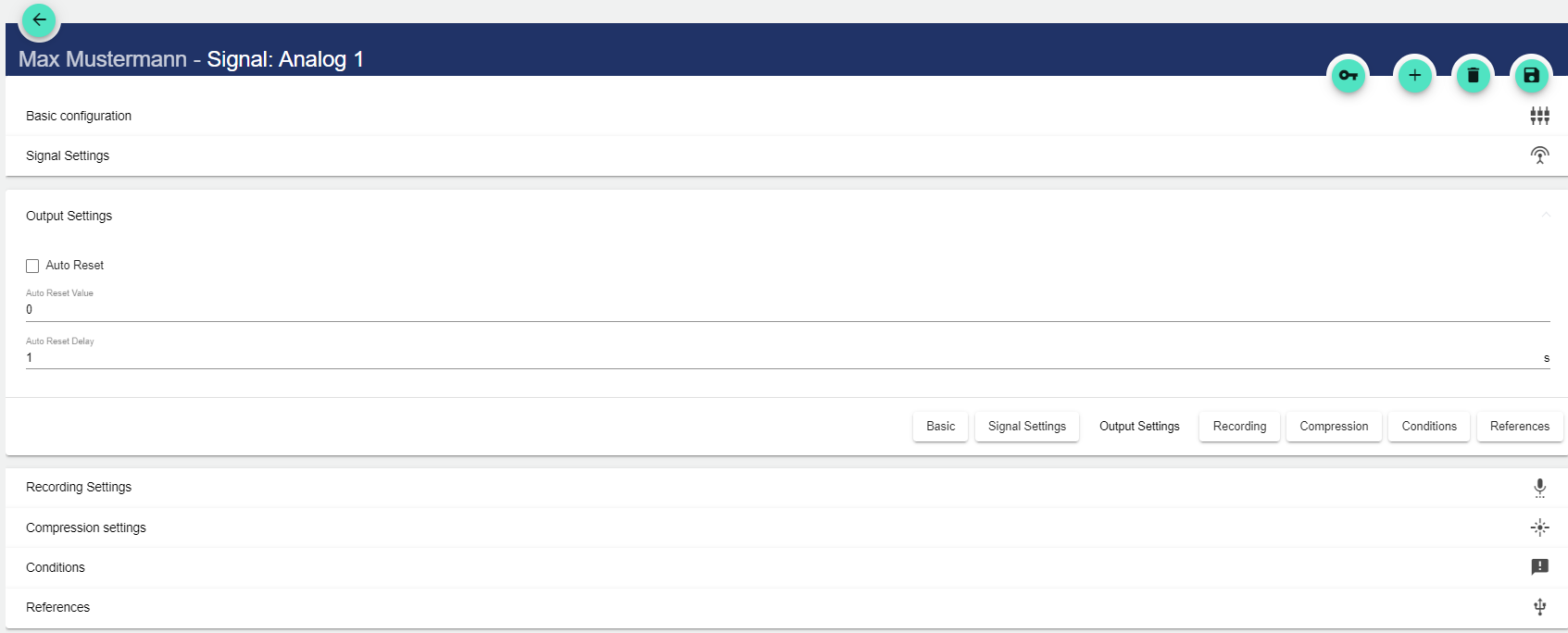

Output settings

This setting option is only available for analog and digital output signals!

-

In the output settings, a value can be specified to which the signal is set with the "Automatic reset" function, after it has been sent to the IoT device.

-

It is also possible to set a delay (in seconds) for the automatic reset of the output signal.

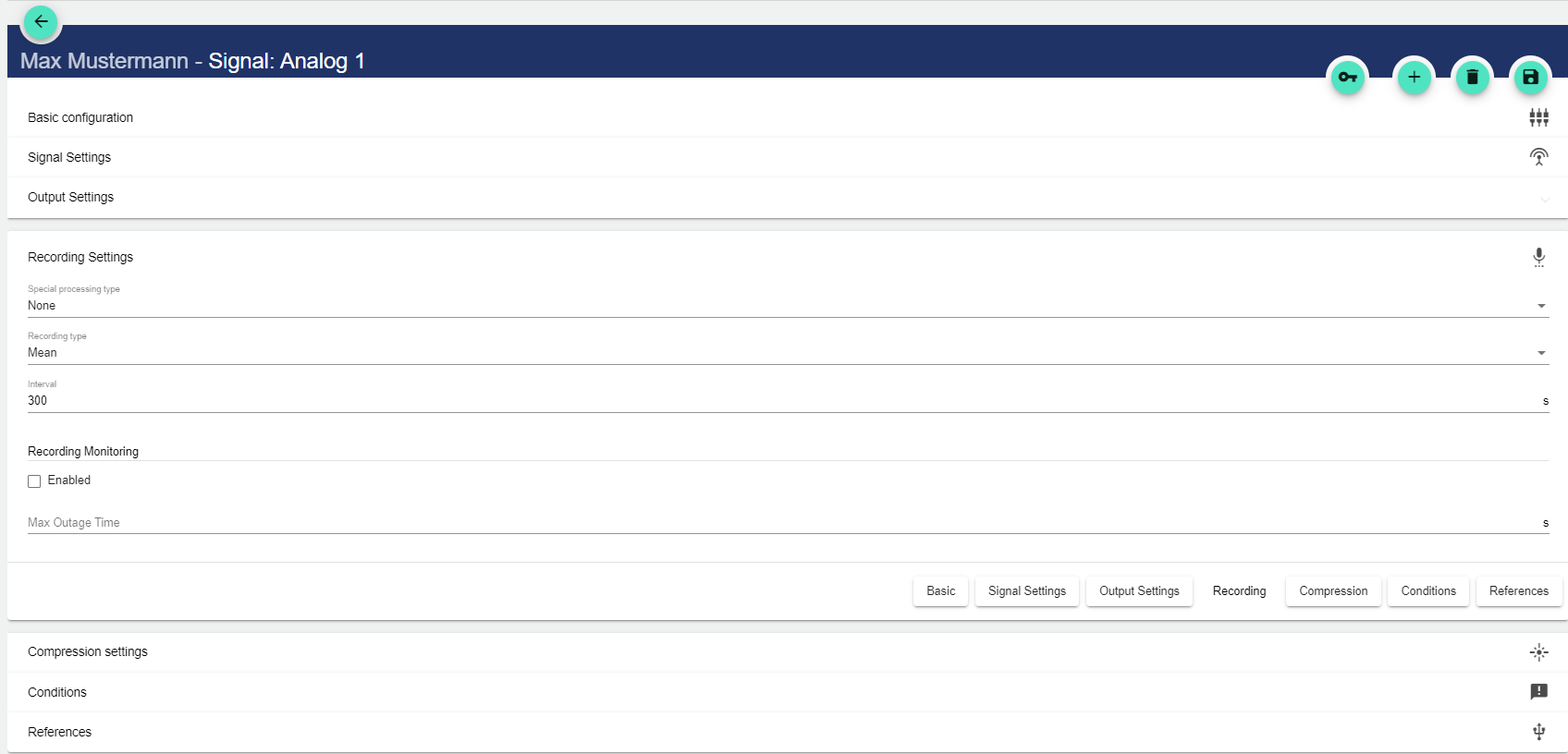

Recording settings

Select special processing type:

-

None

-

Live flow meter: Displays the current flow rate.

-

Watchdog: Used to detect failure of the digital system.

-

Select recording type:

-

Average value

-

Last measured value

-

-

Select the interval at which the last measured or average value is to be queried. The interval is specified in seconds.

Under "Interval", the interval in seconds is specified at which the IoT device (JUMO variTRON) transmits the signal data to the IoT platform.

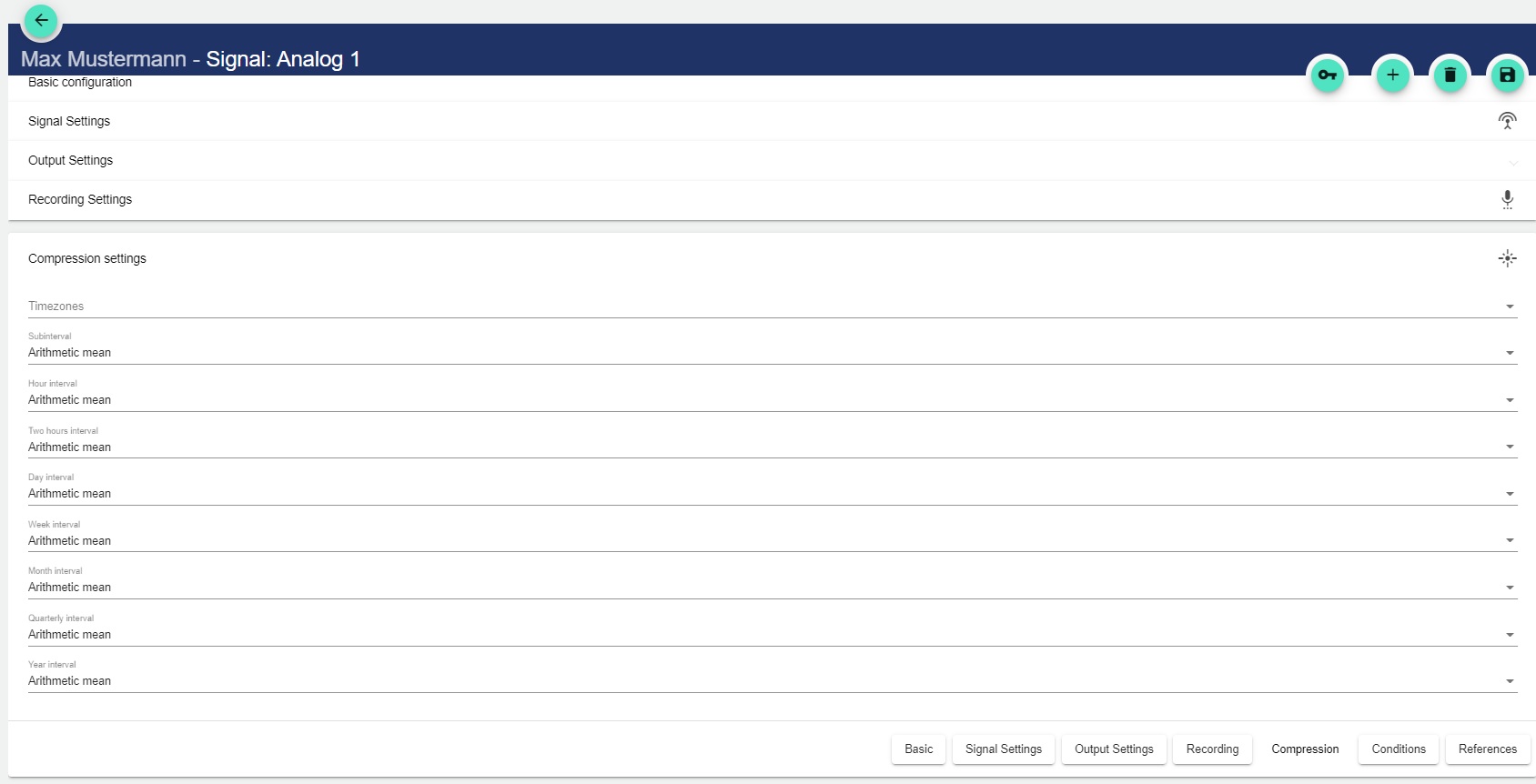

Compression settings

Under Time zones you can set in which time zone the collected data will be stored in the system. If time formats do not fit, a fixed time zone can be selected manually here.

The following interval types are available for selection:

Process Interval refers to the normal transfer rate selected in the Recording Settings area.

|

Interval Type |

Description |

|

Minor interval |

Equivalent to 15 minutes and is therefore the smallest interval. |

|

Hourly interval |

Equivalent to one hour and thus 4 times the minor interval. |

|

Two-hourly interval |

Equivalent to two hours and thus twice the hourly interval. |

|

Daily interval |

Equivalent to 24 hours and thus 12 times the two-hourly interval. |

|

Weekly interval |

Equivalent to 7 days (168 hours) and thus 7 times the daily interval. |

|

Monthly interval |

Equivalent to 30 days (720 hours) / 28 days (672 hours) / 29 days (696 hours) / 31 days (744 hours) and thus approximately 4 times the weekly interval. |

|

Quarterly interval |

Equivalent to 90 days (2160 hours) / 91 days (2184 hours) / 92 days (2208 hours), and thus approximately 3 times the monthly interval. |

|

Yearly interval |

Equivalent to 365 days (8760 hours) / 366 days (8784 hours) and thus 4 times the quarterly interval |

When you fill in the following fields, a drop-down menu opens in each case:

|

Setting |

Description |

|

None |

The value is not recorded. |

|

Weighted average |

The average value is evaluated taking account of the duration of the filling levels or states. |

|

Arithmetic average |

The average value is calculated from the sum of the measured values divided by the number of values. |

|

Difference |

The difference between two selected variables is calculated. |

|

Sum |

Totals all underlying records. |

|

Time |

A time record is generated. |

|

Text |

- |

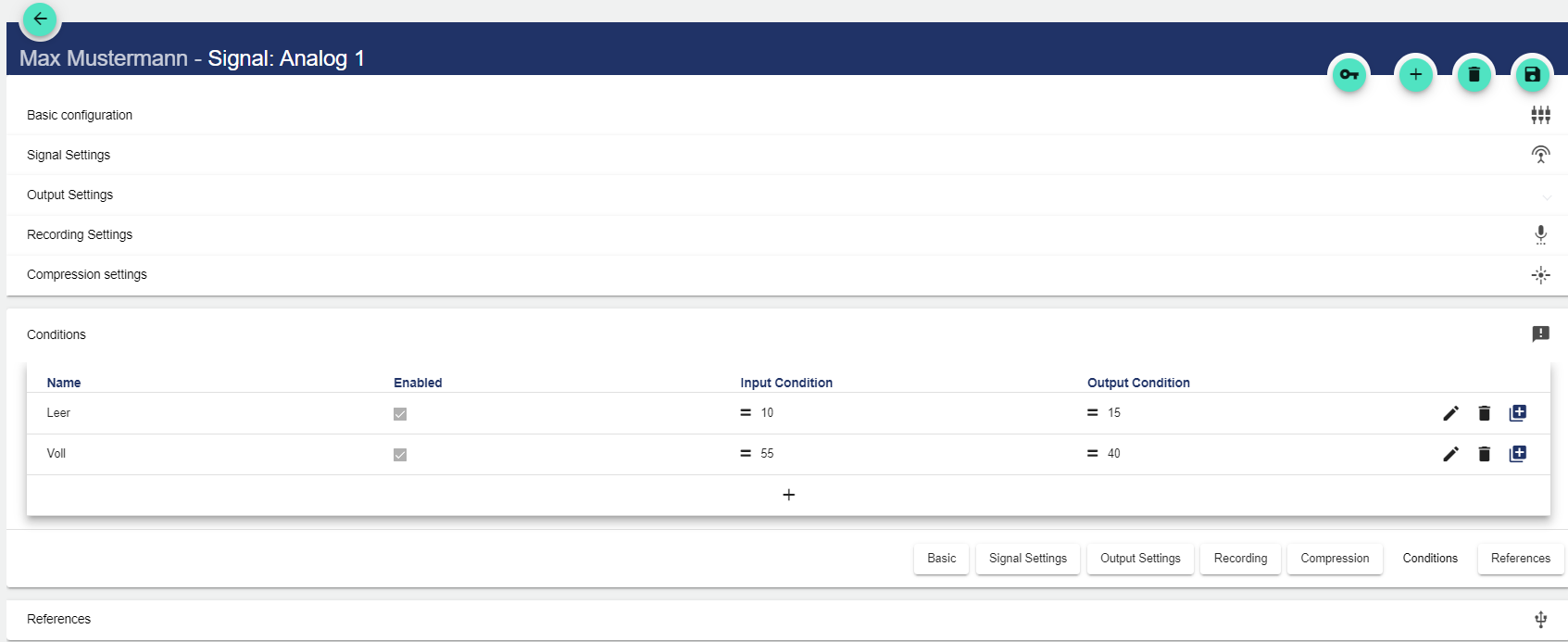

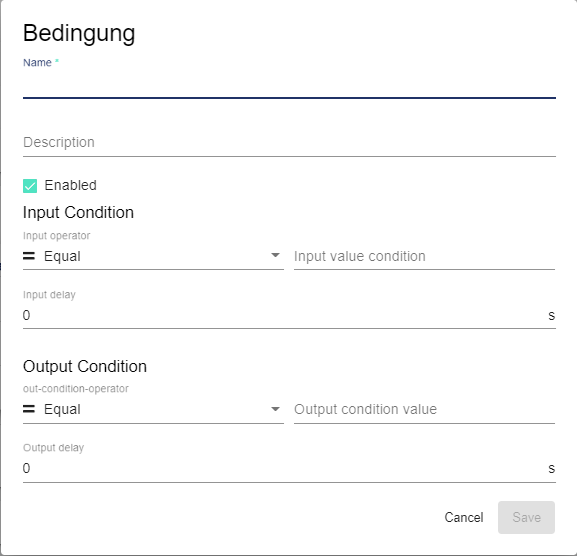

Conditions

Before editing the conditions, the basic configuration must be saved!

-

Assign a name to the condition.

-

Assign an optional description text.

-

If the check mark is set in the "Enabled" field, enable the conditions.

-

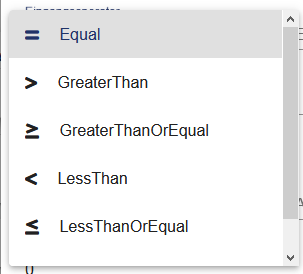

Assign input operator. This serves as a comparison operator and defines the time from which the condition is fulfilled.

-

Assign comparison value 1.

-

The input delay specifies the time in seconds during which the condition must at least be fulfilled.

-

Assign output operator. This serves as a comparison operator and defines the time from which the condition is no longer fulfilled.

-

Assign comparison value 2.

-

The output delay specifies the time in seconds during which the condition must no longer be fulfilled.

References

All references of the signal are displayed.